CNC Machining Service

- CNC MILLING

- Eletrical Discharge Machining

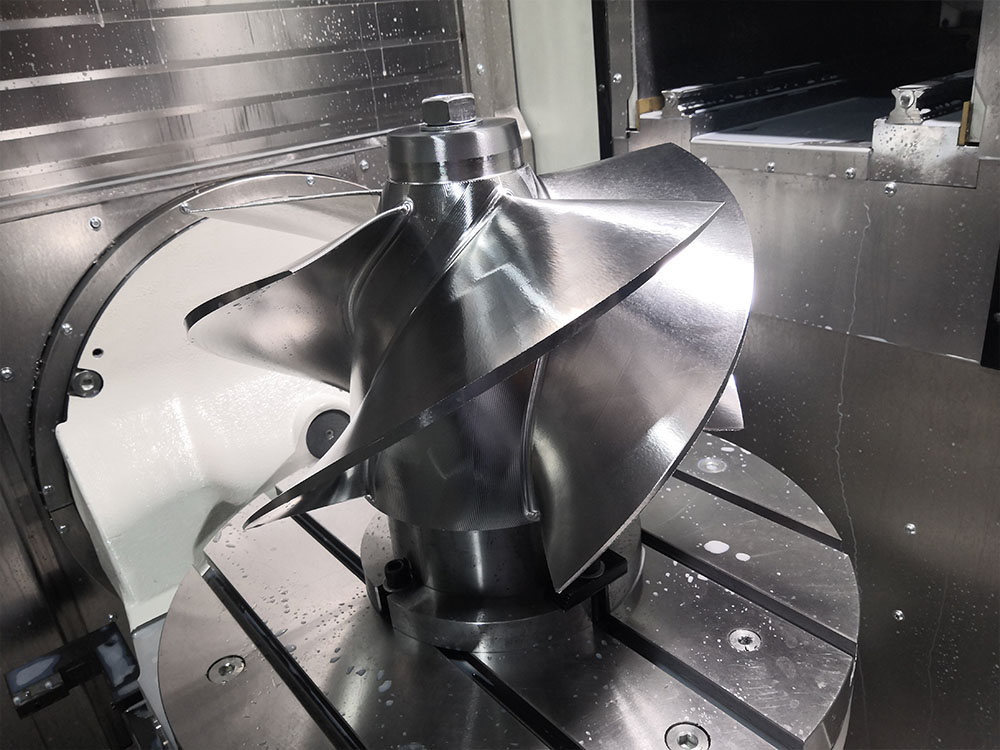

- 5-axis processing.

- CNC Turning

- Gear Hobbing

- More than 200 sets of CNC equipment

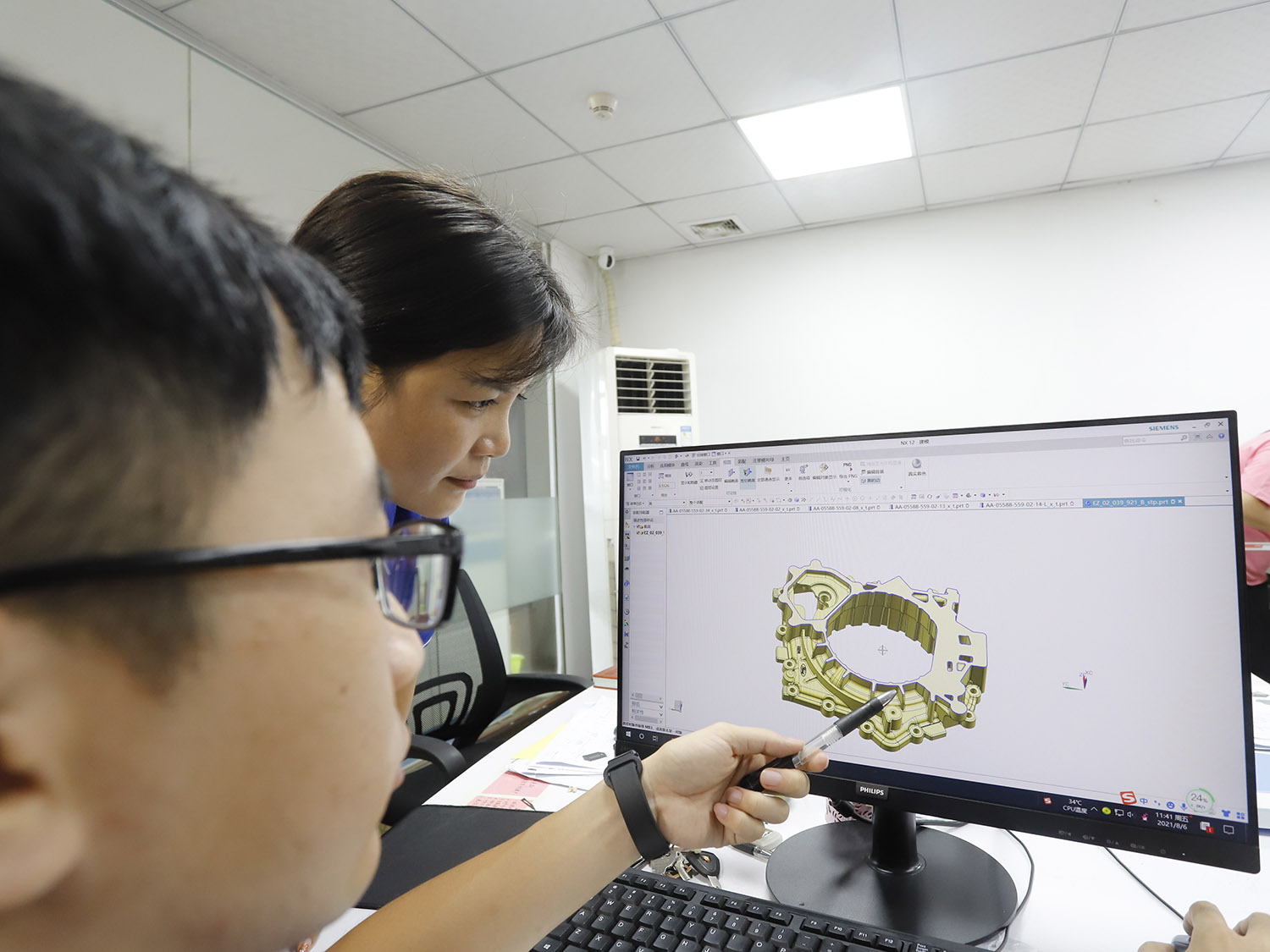

CNC machining service of GREFEE

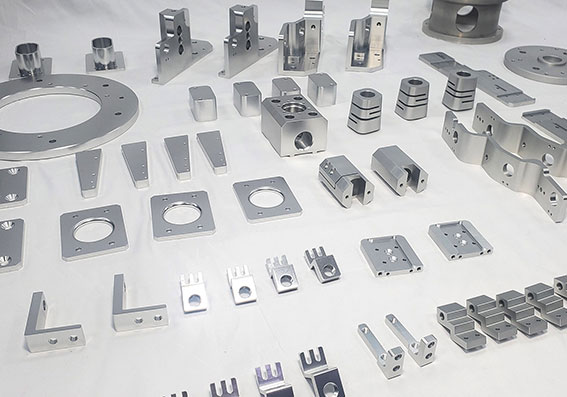

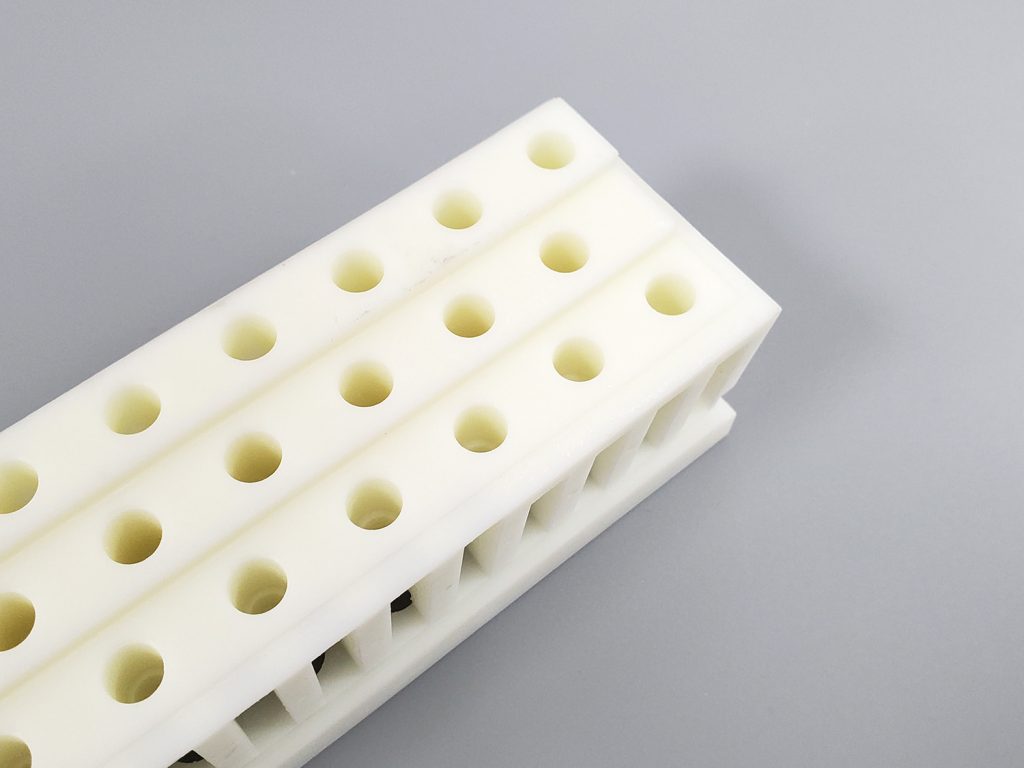

- We have 200+ CNC processing machines, with maximum stroke 2800mm. 6 CNC digital controlled lathe, 5 CNC millers, 7 CNC grinders, 3 EDMs, 1 tapping machine, 1 CMM, 1 2D Measuring Projector and other 18 test instruments.

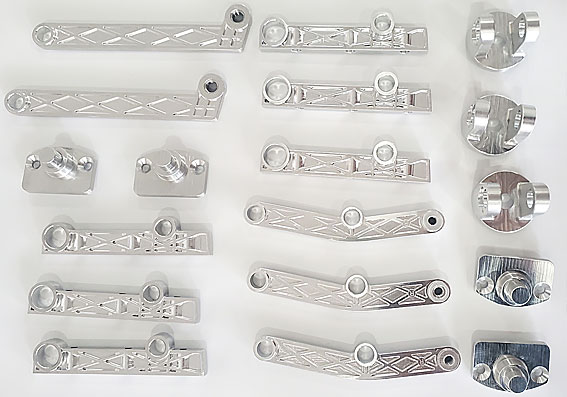

- Our skilled technical engineers complete your custom-made product, components, and small batch production combine milling, turning, EDM, wire-cutting, surface grinding and more other technologies.

- No MOQ, no matter 1 piece or many quantities, we can manage it.

- GREFEE has many types numerical control machines, can complete prototype and production components within 1 day, and small batch components 3-10 days normally.

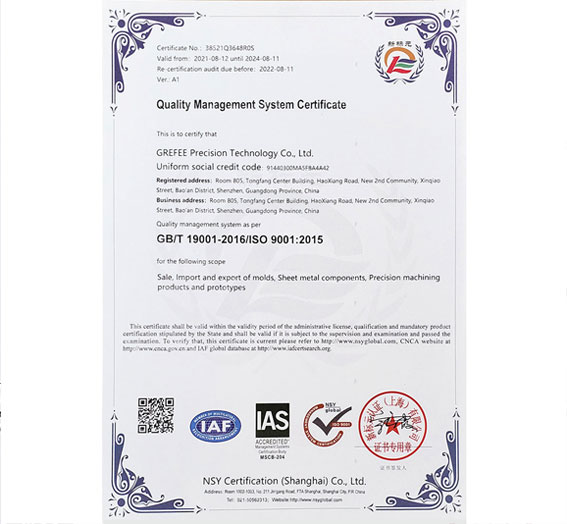

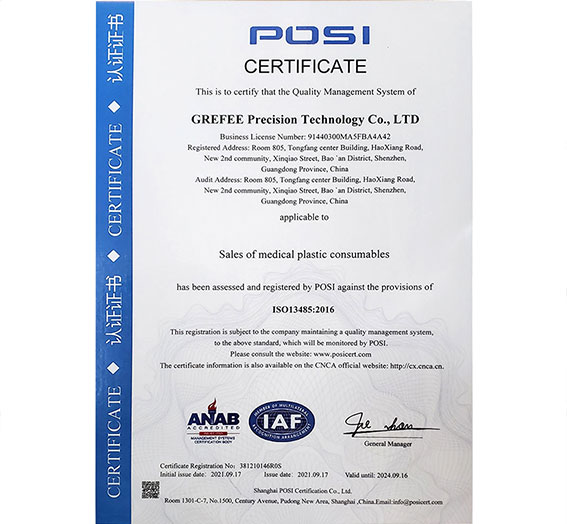

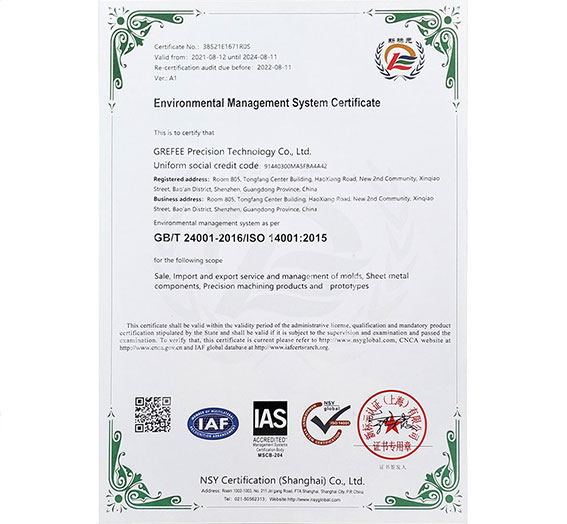

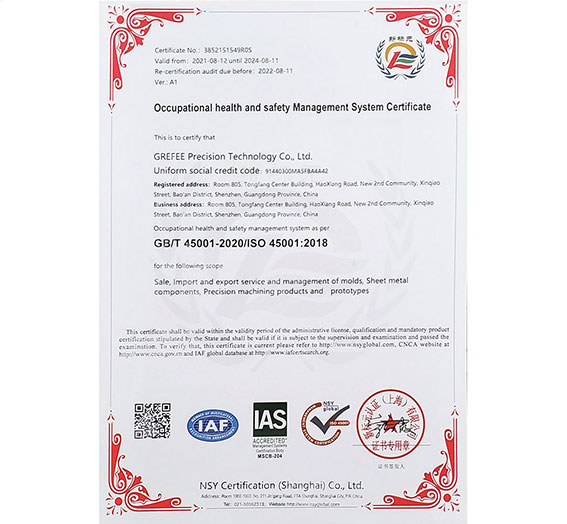

- We strictly follow ISO 9001, can meet tolerance +-0.002mm and provide full-scale dimension test of CNC machined components before shipping as customer required.

- CNC machining quantity range: 1-100Kpcs, we like custom-made rapid prototypes CNC machining.

- Contact us and get free quotation and product assessment

- Click offside video to have a quick look of GREFEE’s CNC machining workshop

Our Merits

16+ industry experience

Domplete urgent component within 1 day

provide full-scale

+-0.002 highest accuracy

7*24 service

provide material certificate of qualification

CNC machining service

CNC MILLING Service

CNC Turning Service

Electrical Discharge Machining

Gear Hobbing

GREFEE’s custom-made CNC machining flow

GREFEE holds the idea that custom-made CNC machining needs consider the product structure design meet the confirm to the rationality and economy of actual manufacturing before CNC machine a new product.

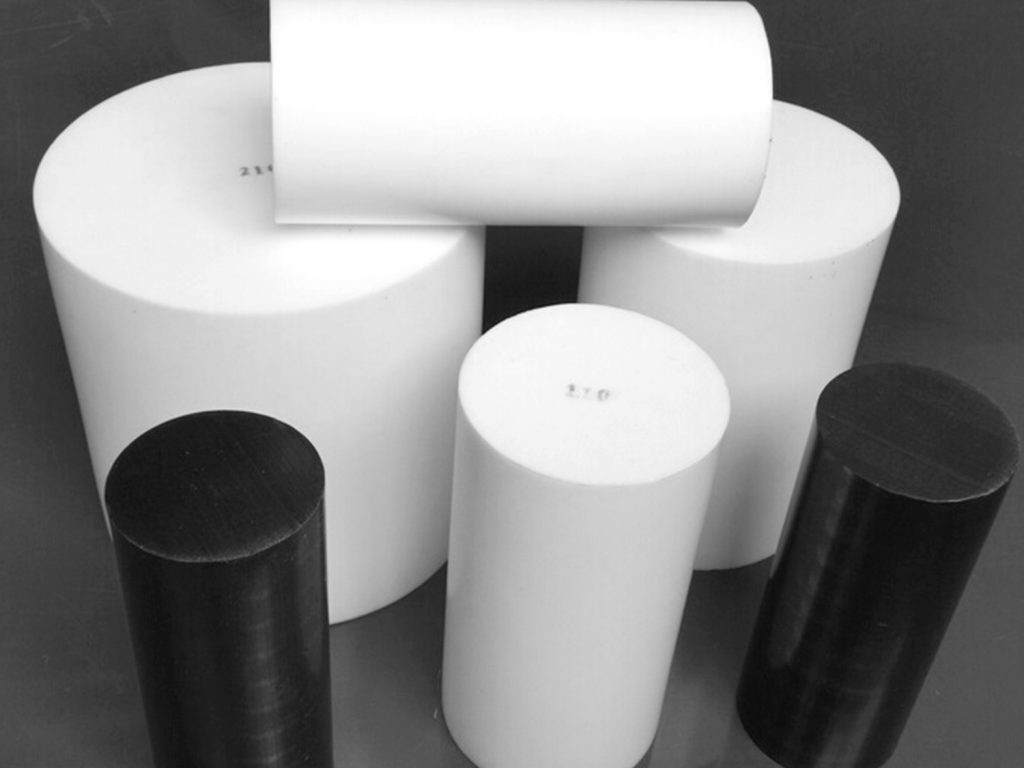

CNC machining resource

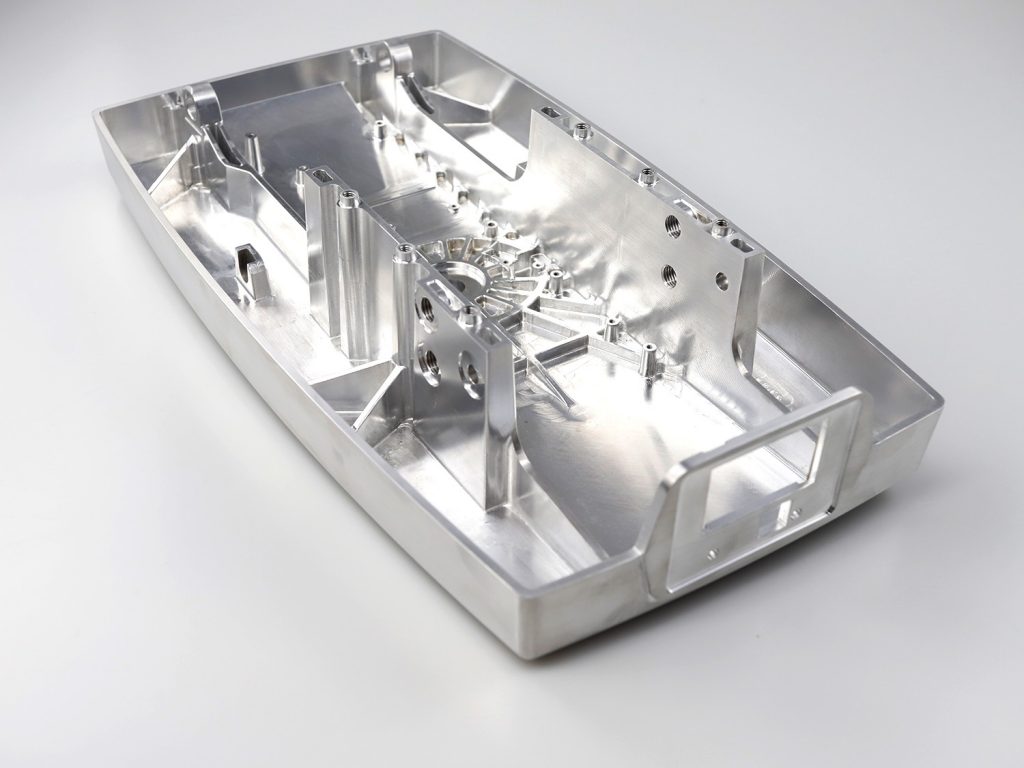

Aluminum alloy CNC machining

Copper CNC machining

CNC machining of stainless steel

CNC machined steel parts

Plastic CNC processing

CNC machining of titanium alloy

CNC machining of magnesium alloy

Zinc alloy CNC machining

CNC machining of nickel alloy

CNC machining of customized materials

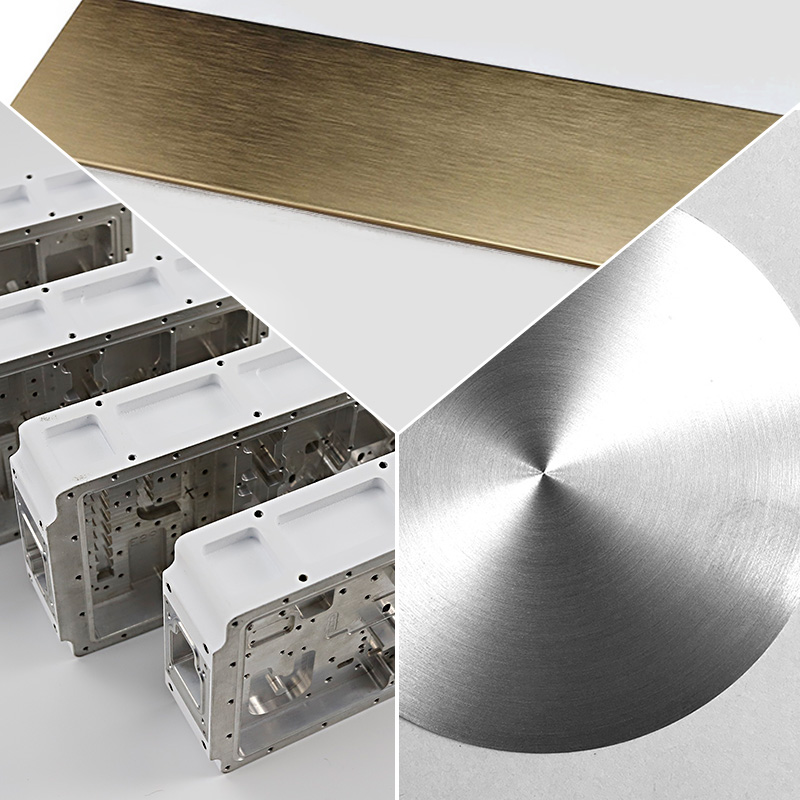

CNC Machining Finishes

We can do all the post-treatment processes on the market. They can bring different effects, appearance, performance, or service life to your parts.

Anodizing is an electrolytic process which converts the surface of metal parts into a protective film.The natural oxide layer increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal does.In GREFEE you can also choose Electroplating,Electrophoresis,Passivation,Black Oxide(Blackening),QPQ,etc.

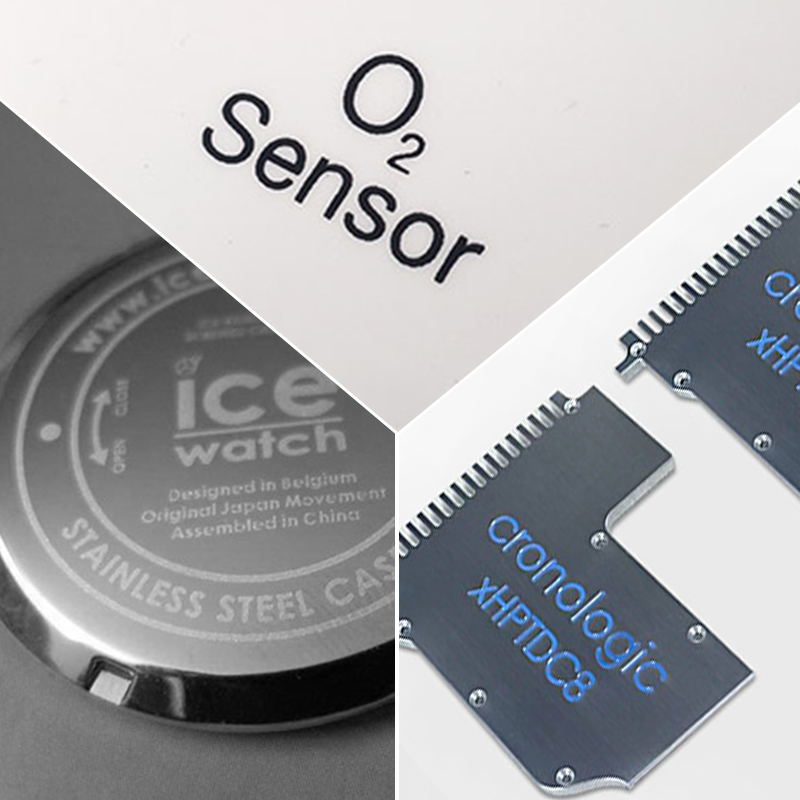

Radium carving, also known as Laser engraving or laser marking, is the practice of using optical principles to engrave logo or pattern on products surface. Radium carving effect is permanent and has high surface quality. It is suitable for all kinds of metal and plastic products. In GREFEE you can also choose Laser Engraving,Silk screen printing,polishing,Brushing finish,Sandblasting.

Powder coating and painting are two normal surface finishes in metal parts. It’s also been commonly applied in precision parts and small batch customized products.

It is usually used to form a hard finish that is tougher than conventional paint which can protect the surface from corrosion and rust, and can also provide a beautiful surface. In GREFEE you can also choose Teflon Coating.

Precision Machining Tolerance

| Metal,PEEK | Other plastics | No drawing | |

| Linear dimension | ±0.01mm/±0.0003in | ±0.05mm/±0.002in | ISO2768 Medium |

| aperture diameter | ±0.008mm/±0.0003in | ±0.05mm/±0.002in | ISO2768 Medium |

| Shaft diameter | ±0.004mm/±0.0016in | ±0.05mm/±0.002in | ISO2768 Medium |

From prototype to production

- Appearance inspection: new product is visible but unreachable in software, but prototype can present the result of new product development.

- Structure design inspection: CNC prototype can present assembling function, can reflect directly whether the product structure is reasonable, and the assembling complexity, which is helpful for discover problems timely and solve them.

- The risk of making mould directly: As the cost of making mould is very high, when mould is in process, problems appear like structure unreasonable or others, which will cause huge loss, while making prototypes can decrease such kind of risk.

- xhibit product in advance: CNC rapid prototyping is fast can economical, can be used for product advertising and exhibiting before mould massive production, or even early marketing and production preparing.

- Low volume production

- When uncertain the market prospect, you can choose low-cost low-volume production for trial.

- Quickly win market: comparing scale production, low-volume production can come into the market quickly, one batch production for a trial usually can be completed 2-15 days, which save your time and mould cost.

- GREFEE provide one-stop manufacturing service, form prototype CNC machining to massive production, we know your needs better and can provide your best solutions.

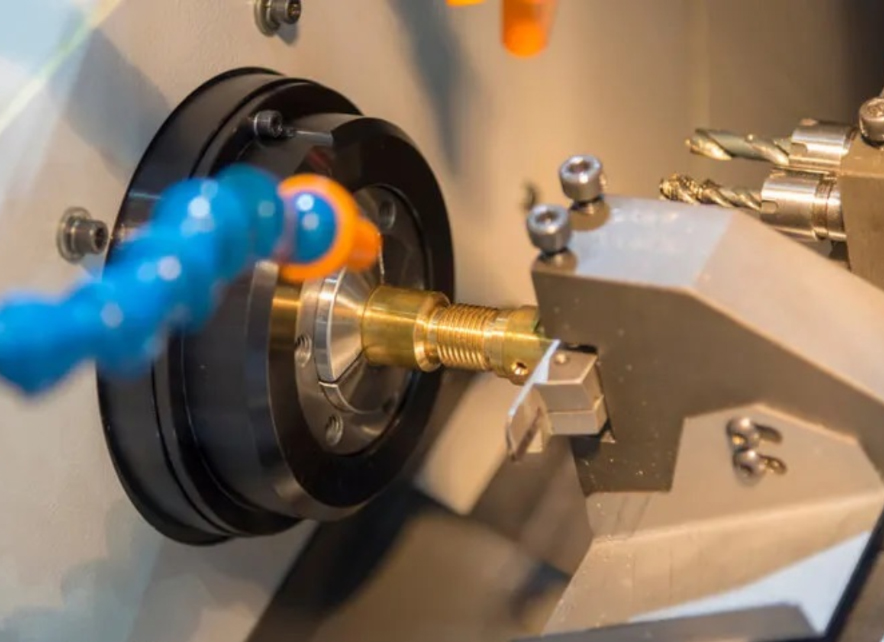

CNC machine for brass parts

GREFEE also has rich experience in processing copper, process material including copper and various alloys of copper, such as brass, bronze, red copper(pure copper), cupronickel. Among them, brass is the most commonly used CNC processing materials, after the completion of processing, copper parts can also be electroplated (galvanized, nickel, chromium) processing.

Industry application of CNC machining

GREFEE provide one-stop CNC machining service, we know the requirements of CNC machining components from every industry, which let us have advantages in dealing with customer’s particular needs.

From CNC machining prototype to massive production, for each different project from different industry, we accumulated rich experience.

Robotic

CNC machining can be used for robot parts, such as arm, foot, head and other control connecting parts.

Automobile

CNC machining can be used for automobile engine, steering gear, bearing, wheel hub, etc

Medical devices

CNC can manufacture medical equipment parts, vulnerable parts, high-precision parts and link parts.

Mechanical

CNC can manufacture mechanical equipment parts, vulnerable parts, high-precision parts and link parts

Aerospace

CNC can manufacture aircraft engine parts, cabin links, etc.

Automation

CNC can manufacture power parts of automation equipment, supercharger parts, links, etc.

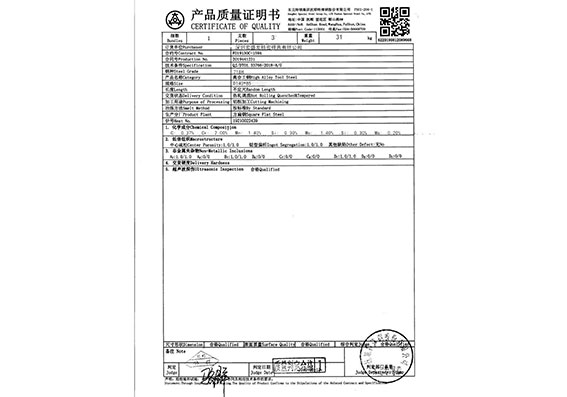

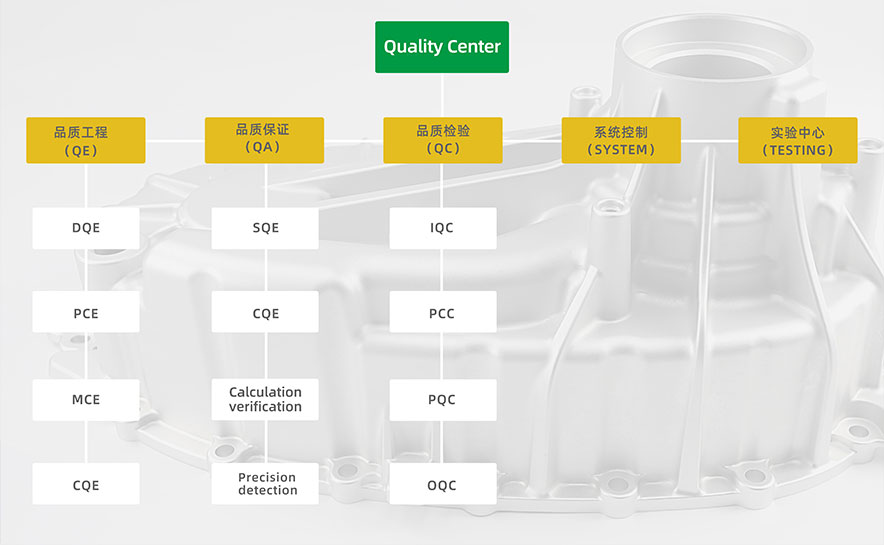

Quality Assurance

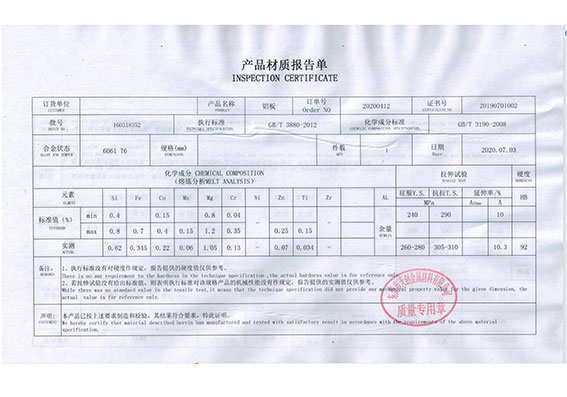

- GREFEE set a complete management and quality control flow from material-stock, manufacturing, and delivery. Inspect every process, provide full-scale QC report and certification and certificate of quality for material.

- We insist every part keep the following inspect steps:

- All materials are inspected and recorded before production, to make sure the accuracy of material.

- Manufacturing process inspection:In manufacturing, FAL is in every process and checked by QC manager.

- Warehouse inspection,Warehouse inspection

- Inspect again, record, and attach delivery report before shipping

- Facility inspection:Revise and identify facility termly

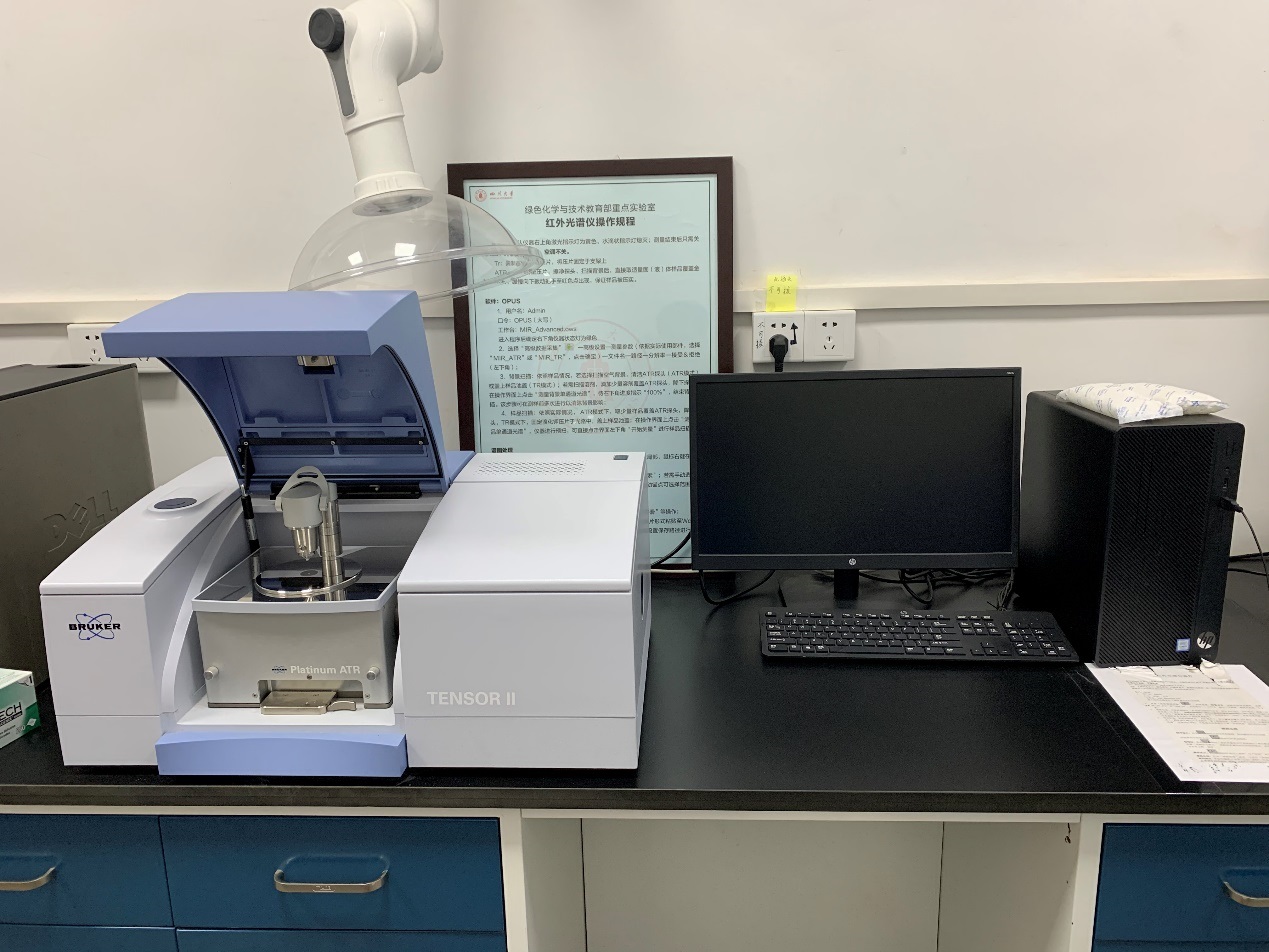

CMM is a measurement method of geometric elements, including point, line, surface, circle, sphere, cylinder, cone, etc. Based on coordinates of three-dimensional space, CMM can continually scan the part with complicated precise dimension, shape and tolerance, and the surface of high-precision geometric, and also mechanical parts with complicated shapes, and then achieve part inspection, shape measuring, and process control. CMM is widely used in industries of precision accessories, precision mould, precision manufacturing, military, aerospace and automobile making.

Spectrum analyzer:Spectrum analyzer can detect raw material ingredient in raw material feeding, it can quickly test the ingredient and element proportion of raw material, and its accuracy can meet laboratory requirements. It can identify the reality of material fast.

2D image measuring:2D image measuring is based on CCD digital image, relying on computer screen measurement technology and powerful software ability of space geometry , It can read the displacement value of the optical ruler quickly, for the operator to make image contrast and measure, then quickly and intuitively distinguish the possible deviation of the measurement results. Generally it is used in simple hardware components and prototype model.

Other inspection equipments:esides, GREFEE has height gauge, hardness tester, all kinds of internal and external thread, micrometer, caliper, etc., All these inspection equipments are used for quality control testing, to make sure the product quality meet demands as customer required.

GREFEE strictly execute ISO standard, to make sure product quality and lead time, and pay a return visit regularly and conduct satisfaction survey, accepting feedbacks from customers, which improves our team constantly.

Why GREFEE

- Competitive price: rely on GREFEE’s excellent comprehensive strength, our price on CNC machined products is 25% lower than that of companions.

- Fully equipped: we choose appropriate technology and machine to machine your products based on product demands and characters to suit your needs any time.

- Strict quality control: every component is after 5 testing procedures, to make sure all parts are 100% qualified delivery.

- Project progress: GREFEE values lead time control on each project, provide photos of processing progress every week, and also processing schedule.

- Submit your project?

Customer cases in CNC machining

Automobile parts case

Medical parts case